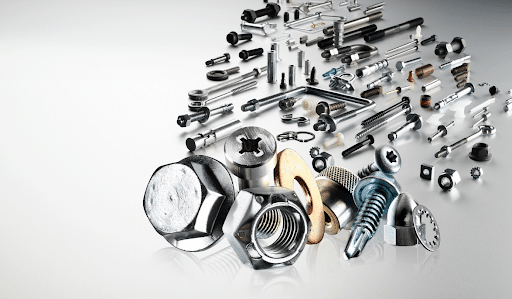

Whether you’re a seasoned contractor or love tackling do-it-yourself projects, hardware fasteners are an essential part of any task. From threaded inserts to plated steel eyebolts, the variety of fasteners available can seem overwhelming. Let’s break down the different types of fasteners, their advantages, and how to choose the best one for your next project. If you want to take a deep dive into home hardware, don’t forget to check out our guide on unveiling the ultimate home hardware.

What is a Hardware Fastener?

A hardware fastener is a mechanical device that is used to join two or more objects together. Some common examples of hardware fasteners include nails, screws, bolts, nuts, rivets, and clips. Hardware fasteners work by creating a force that holds the objects together, either through friction, tension, or compression.

The use of hardware fasteners allows objects to be assembled and disassembled repeatedly. Fasteners are often used in construction, manufacturing, and maintenance because they provide a way to build stable structures while still allowing the flexibility to take things apart for modifications or repairs.

Be sure to check out our guides on ensuring safety with security hardware and elevating design with furniture hardware to learn more about how fasteners and other components impact home projects and design.

How Threaded Inserts Can Be Used in Different Projects

Threaded inserts, also known as threaded metal inserts, are incredibly versatile fasteners that allow you to create strong, reusable, threaded holes in materials like plastic, wood, and sheet metal. They can be used in a wide variety of projects and applications. For example, threaded inserts are commonly used when assembling furniture to securely fasten table legs or attach shelving to materials like wood, plastic, and particle board. They are also installed in plastic electronic enclosures and equipment cases to allow screwed connections for things like panels, PCBs, and cable glands.

Threaded inserts enable you to create threaded holes in materials to mount brackets, guards, panels, or other hardware on machinery. They can also be installed in cabinet doors and panels to allow hinges, handles, and hardware to be securely fastened. Threaded inserts are incredibly handy fasteners that have widespread use in furniture, enclosures, automotive, appliances, machinery, doors, cabinets, and outdoor equipment.

Advantages of Using Threaded Inserts

Threaded inserts offer many benefits for construction and installation projects. The metal threads in the inserts are much stronger than threads tapped directly into materials like plastic and wood, so they won’t wear out or strip over time. Threaded inserts can be installed in almost any material – wood, plastic, particle board, sheet metal, composites, fiberglass, and more. This wide material compatibility makes them versatile for many applications. The inserts provide excellent vibration resistance, so they won’t come loose over time like some fasteners can.

By using threaded inserts, you can often use thinner and lighter materials in your projects while still retaining strong threaded connections. The inserts are frequently made from stainless steel or brass, giving them good corrosion resistance for outdoor use. In many cases, you can install threaded inserts using just basic tools like a drill rather than specialized equipment. The inserts distribute load stresses evenly, which helps prevent cracking in brittle materials. Finally, threaded inserts give a clean, low-profile finish to your projects instead of visible or protruding fasteners. Their strength, reusability, and professional look make threaded inserts a great choice for all kinds of construction and installation work.

How to Choose the Right Threaded Inserts for Your Project

When selecting and using threaded inserts, there are several important factors to consider for optimal performance in your application. First, pick an insert material suitable for your base material, such as plastic, wood, or metal. Heat-set inserts designed for thermoplastics often work best. You’ll also want to choose a thread type and size that matches your bolts, with common metric sizes being M3, M4, M5, and M6 and common imperial sizes being #4, #6, #8, #10, and #12. Size the insert length to match the thickness of your material, allowing a small protrusion. A flange or knurl on the insert can help prevent turning in soft materials like wood.

Consider the installation method as well – self-tapping inserts for wood, press-in style for plastic and metal, or heat-set for thermoplastics. Material-wise, steel provides strength while brass increases corrosion resistance and stainless steel is ideal for outdoor use. Be sure to drill a proper pilot hole for ease of installation and follow the size recommendations. Use the right installation tools, like a tap and insertion tool for self-tapping inserts in wood. Verify the insert meets your application’s pull-out and torque requirements.

Use thread locker or adhesive when needed to secure the insert and prevent turning in materials like wood and plastic. Allow proper curing time, as some inserts require time to fully cure the adhesive or heat-set. Specialty inserts like EMI/RFI shielding, nylon locking, and extra long are available when specific needs arise. If you’re ever unsure about selection or usage, seek advice from insert manufacturers and suppliers. Following these tips will ensure optimal insert selection and usage for your particular application.

Using Stainless Steel and Galvanized Steel as Hardware Fasteners

Stainless steel and galvanized steel are two excellent options for hardware fasteners in many applications due to their durability, strength, and resistance to corrosion.

Stainless steel contains chromium, which forms an invisible passive layer of chromium oxide when exposed to oxygen. This protective layer prevents corrosion and staining, providing excellent rust and corrosion resistance. Stainless steel hardware maintains its smooth finished look over time.

Galvanized steel is coated with a layer of zinc using a hot-dip galvanizing process. The zinc acts as a barrier, preventing oxygen from reaching the steel and providing excellent corrosion resistance. The galvanized coating significantly slows down the rate of corrosion if the coating gets scratched or damaged.

Characteristics of Stainless Steel Hardware Fasteners

Stainless steel is an ideal material for hardware fasteners due to its high strength, durability, and corrosion resistance. Stainless steel has excellent tensile strength, allowing hardware fasteners made from it to be rated for heavy load capacities. The chromium in stainless steel prevents surface rust and corrosion even in harsh outdoor conditions or humid environments, enabling it to maintain its smooth finish for decades.

Stainless steel also withstands high and low temperatures while retaining its strength, making it suitable for both indoor and outdoor applications. With its attractive, modern look and ability to resist scratches, stainless steel offers aesthetic appeal. Its nonporous surface also makes stainless steel hardware fasteners easy to sanitize in applications requiring hygiene. With various alloys and grades optimized for factors like strength, weldability, and corrosion resistance, stainless steel provides versatile options for durable, high-performing hardware fasteners across many uses.

Choosing Galvanized Steel for your Hardware Fasteners

When choosing between stainless steel and galvanized steel hardware, consider the specific demands of the application. Stainless steel is best for highly corrosive or sanitary environments. Galvanized steel provides excellent corrosion resistance at a lower cost but requires occasional maintenance of the coating. Consult an expert if you’re unsure which material is optimal for a project.

Proper installation is also critical for taking full advantage of stainless or galvanized steel’s corrosion resistance. Use compatible metals and isolation materials as needed. Keeping surfaces clean and dry will maximize the lifespan of any hardware fastener.

With routine inspection and maintenance, quality stainless steel and galvanized steel fasteners will provide decades of reliable performance in demanding indoor and outdoor applications.

Fasteners are deceptively simple devices that provide immense utility across industries and applications. Their dependable fastening power enables us to build, create, and innovate, while their ongoing advancement promises ever more capable, specialized, and optimized fastening solutions.

Insider Insights from High Performance Home

High Performance Home is your source for the latest information and insights on home design and the housing industry. Our website features blogs and articles to keep you up-to-date on home trends, sustainability practices, smart home technology, and more. Our mission is to connect and educate all those with a passion for building, remodeling, and advances in the modern home.

If you’re looking for home inspiration, see our kitchen page and see our gathering page for ideas, or browse our page on hardware in bathrooms for more insight.

Frequently Asked Questions

What are five basic types of fasteners?

There are several basic types of fasteners including screws, bolts, nuts, rivets, nails, and clips. Screws are threaded fasteners that can be driven into materials using a screwdriver or drill. Bolts are similar to screws but require a nut to be threaded onto the opposite end. Nuts are threaded inside to receive bolts or machine screws. Rivets are tubular shafts that are inserted into holes and deformed on one end to hold materials together. Nails are tapered, rigid shafts that are hammered into materials. Clips are bent pieces of metal that grasp materials.

Are fasteners considered hardware?

Yes, fasteners are considered hardware. Hardware includes any physical piece of equipment used in construction, machines, furniture, tools, and more. Along with fasteners like screws and bolts, other examples of hardware include hinges, latches, springs, clamps, pipe fittings, brads, and washers. Hardware items are commonly made of durable materials like metal, plastic, or rubber.

What are standard fasteners?

Standard fasteners refer to common fastener types that conform to industry specifications on dimensions, strength, and thread patterns. For example, there are standard sizes and thread types for screws, bolts, and nuts. Using standard fasteners allows parts from different manufacturers to be joined and replaced.

Selecting the perfect cabinetry to meet your client’s needs can be challenging with the endless options available. As a builder, you want

Read More →Are you thinking of upgrading your kitchen and wondering where to start? Have you considered adding a warming drawer to enhance both

Read More →Shopping for a new freezer can be a daunting task. With a range of different types, features, and brands to choose from,

Read More →In the world of construction, appliances need to meet specific requirements that revolve around functionality, durability, and cost-effectiveness. This guide is dedicated

Read More →